The global transportation landscape is undergoing a radical transformation.

As the world pivots away from internal combustion engines (ICE) to mitigate climate change, the demand for sophisticated Electric Mobility Battery Solutions has reached an all-time high.

At the heart of this revolution is the lithium-ion battery—a technology that has evolved from powering small consumer electronics to driving heavy-duty transit systems.

Introduction: The Electrification Paradigm Shift

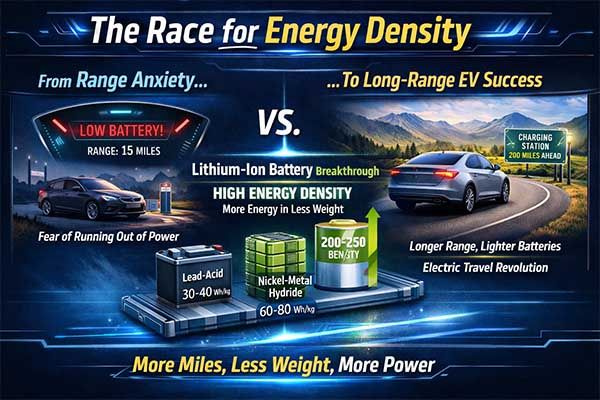

The transition to electrification is fundamentally a race for energy density.

For decades, the primary hurdle for electric vehicles (EVs) was “range anxiety”—the fear that a vehicle would run out of power before reaching a charging station.

The breakthrough came with the advancement of lithium-ion chemistry, which offers significantly higher energy density (measured in Wh/kg) compared to older lead-acid or nickel-metal hydride systems.

This high density allows manufacturers to pack more energy into smaller, lighter footprints, making long-range electric travel a practical reality.

Application: Expanding the Horizons of Mobility

While electric bicycles and mopeds have dominated urban centers, the true potential of high-performance battery solutions lies in more complex and heavy-duty applications. Beyond the realm of two-wheelers, lithium-ion technology is revolutionizing several key sectors:

- Passenger & Commercial Vehicles: From long-range Tesla-style sedans to last-mile delivery vans and heavy-duty electric trucks.

- Public Transit: Electric buses that require massive battery arrays to support all-day operation and rapid “opportunity charging” at terminals.

- Specialized Medical & Accessibility Mobility: This sector is critical for social inclusivity. High-reliability battery packs are now the standard for the modern Electric Wheelchair, providing users with the confidence of all-day range and lightweight portability. Similarly, the electric mobility scooter has benefited from lithium-ion’s ability to provide high torque for inclines while remaining easy to charge at home.

- Industrial & Material Handling: Automated Guided Vehicles (AGVs) and electric forklifts in warehouses that require 24/7 uptime and fast-charging capabilities.

Key Requirements for Modern Battery Solutions

To compete with the convenience of gasoline, electric mobility battery solutions must meet three stringent criteria:

- High Energy Density: Essential for achieving the 400+ km ranges expected by modern consumers.

- Fast-Charging Capabilities: The ability to charge from 10% to 80% in under 30 minutes is the new industry benchmark, requiring cells that can handle high C-rates without degrading.

- Extreme Safety Standards: Unlike consumer electronics, mobility batteries operate in harsh environments. Adherence to this standard ensures functional safety, protecting against electrical faults, thermal runaway, and mechanical impact during collisions.

Chemistry Deep Dive: NMC vs. LFP

Choosing the right battery chemistry is a strategic decision based on the vehicle’s intended use. Currently, two chemistries dominate the market:

| Feature | NMC (Nickel Manganese Cobalt) | LFP (Lithium Iron Phosphate) |

| Energy Density | High ($200-300 Wh/kg$) | Moderate ($140-170 Wh/kg$) |

| Cycle Life | Good (1,000 – 2,000 cycles) | Excellent (3,000 – 6,000+ cycles) |

| Safety | Requires advanced Thermal Management | Inherently stable; high thermal threshold |

| Cost | Higher (due to Cobalt/Nickel) | Lower (Cobalt-free) |

| Best For | Long-range passenger EVs, Performance cars | City cars, Buses, Industrial AGVs |

High-performance lithium-ion battery systems developed for electric mobility also serve a wide range of adjacent applications.

In light electric vehicles (LEVs) such as e-bikes, scooters, and delivery robots, the same high-energy and fast-charging battery platforms enable longer range and lighter vehicle designs.

These technologies are further extended into energy storage systems (ESS), where electric-mobility-grade lithium cells provide reliable power for grid support, peak shaving, and industrial backup.

For power tools, electric-mobility battery chemistry delivers high discharge capability and durability, supporting demanding cordless equipment in industrial and construction environments. In recreational vehicles (RVs), lithium-ion mobility batteries provide stable off-grid energy for appliances, climate control, and onboard systems.

Meanwhile, unmanned aerial vehicles (UAVs)rely on lightweight, high-density lithium-ion battery packs derived from electric-mobility platforms to achieve longer flight times, improved safety, and consistent power output.

Thermal Management Systems: The Silent Guardian

In high-performance electric mobility, the battery’s biggest enemy is heat. During rapid acceleration or fast charging, internal resistance generates significant thermal energy. Without effective Thermal Management Systems (TMS), this heat can lead to accelerated degradation or, in extreme cases, thermal runaway.

For passenger vehicles and heavy trucks, active liquid cooling is essential. By circulating coolant through plates sandwiched between battery modules, the system maintains an optimal operating temperature (typically between 15℃ and 35℃). This not only ensures safety but also extends the battery’s longevity, ensuring the vehicle maintains its value over a decade of use.

Sustainability: Life Cycle and Recycling

The “green” credentials of an EV are only as good as its battery’s life cycle. A comprehensive Life Cycle Analysis (LCA) includes everything from raw material extraction to end-of-life processing.

As the first generation of EVs reaches retirement, battery recycling has become a pillar of the supply chain. Methods like hydrometallurgical recovery allow manufacturers to reclaim up to 95% of critical minerals like Lithium, Cobalt, and Nickel. This “closed-loop” system reduces the environmental impact of mining and secures the supply chain against geopolitical volatility.

Manufacturer Spotlight: Long Sing Energy

As a leading factory in the lithium-ion sector, Long Sing Energy specializes in providing end-to-end electric mobility battery solutions. We understand that a “one-size-fits-all” approach does not work in a diverse transportation market.

How We Solve Customer Challenges:

- Customized Engineering: We don’t just provide cells; we design integrated Battery Management Systems (BMS) tailored to specific voltage and discharge requirements.

- Safety-First Manufacturing: Our facility utilizes fully automated assembly lines with X-ray and laser inspection to ensure every cell meets rigorous safety benchmarks.

- Rigorous Testing: Every pack undergoes vibration, immersion, and nail-penetration testing to simulate real-world accidents.

Case Studies:

- Case A (Logistics): Long Sing provided a customized LFP solution for a fleet of electric delivery vans in Europe. By optimizing the BMS for cold-weather performance, we increased their winter range by 15%.

- Case B (Medical Mobility): We partnered with a leading manufacturer to develop a high-density NMC pack for a foldable Electric Wheelchair. The result was a 30% reduction in weight compared to their previous supplier, significantly improving user portability.

Fill out the form below, our expert will help you with the final power decision together: