Lithium-ion Batteries

In-depth insights into lithium-ion battery technology, manufacturing processes, and real-world applications—from cell selection to reliable battery pack assembly.

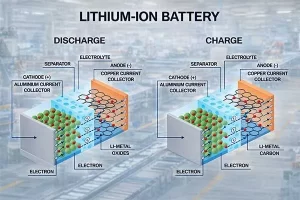

Lithium-ion batteries are at the core of modern electrification, powering everything from electric mobility and light electric vehicles to energy storage systems, power tools, recreational vehicles, and unmanned aerial vehicles. This blog category is dedicated specifically to lithium-ion battery technology, focusing on how these batteries are designed, manufactured, assembled, and optimized for real-world performance.

In this section, we share practical knowledge about lithium-ion battery fundamentals, including cell chemistry characteristics, performance behavior, safety considerations, and application-specific requirements. Rather than repeating generic battery definitions, our articles explore what truly matters in engineering and manufacturing environments—how design decisions affect lifespan, reliability, and total system cost.

You will find discussions that naturally introduce topics such as cylindrical, prismatic, and polymer lithium-ion batteries, explaining how each format behaves under different load conditions and usage scenarios. We also explore how lithium-ion batteries are integrated into complete battery pack solutions, where electrical design, mechanical structure, and thermal management must work together as a system.

A key focus of this category is the battery pack production and assembly process. We share insights into how lithium-ion cells are evaluated, matched, and assembled into packs, including steps such as incoming cell inspection, capacity grading, cell grouping, welding or soldering, BMS integration, insulation design, structural reinforcement, and final performance testing. These processes are critical to ensuring safety, consistency, and long-term stability in lithium-ion battery packs.

At Long Sing Energy, lithium-ion battery production is not treated as a one-size-fits-all process. Our factory works closely with project requirements to determine the most suitable cell type, electrical configuration, and mechanical layout. By controlling in-house assembly and testing, we are able to manage quality at every stage and respond quickly to customization needs.

Our deep understanding of lithium-ion battery manufacturing comes from years of hands-on experience solving real customer challenges. We have helped clients address issues such as inconsistent battery performance between batches, overheating in compact enclosures, insufficient cycle life under high discharge rates, and compliance with international safety standards. Through careful design optimization and process control, we transform these pain points into stable, scalable solutions.

One of our core advantages lies in the combination of engineering support and manufacturing execution. Our team understands how design decisions on paper translate into production realities on the factory floor. This allows us to reduce development risks, improve production yield, and ensure that battery packs perform consistently in mass production—not just in prototypes.

By reading articles in this lithium-ion batteries category, engineers gain clearer design direction, project managers gain better control over timelines and quality, and battery buyers gain confidence in evaluating technical claims versus real manufacturing capability. The knowledge shared here reflects not only industry standards, but also lessons learned from actual production and long-term customer collaboration.

If you are developing or sourcing lithium-ion battery solutions and want a manufacturing partner who truly understands the technology, the process, and the challenges involved, Long Sing Energy is ready to support your project.

Looking for a reliable lithium-ion battery solution?

Click the inquiry button to discuss your application with our team and discover how our factory experience can help you build safer, more reliable, and more competitive battery products.