Lead acid Vs lithium ion battery is one of the most common comparisons in industrial and energy storage applications, as both technologies offer distinct advantages and limitations in terms of performance, cost, lifespan, and system design.

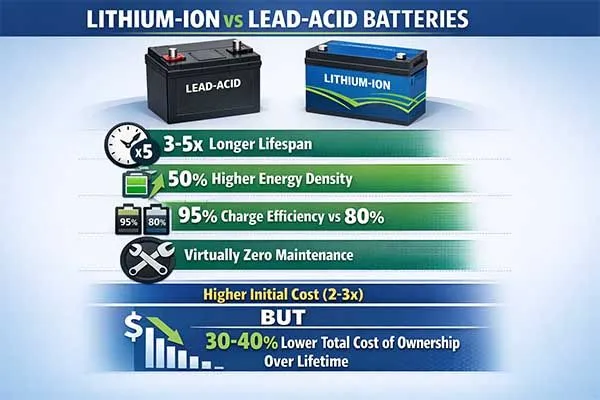

When comparing lead acid vs lithium batteries, lithium ion technology offers 3-5 times longer lifespan, 50% higher energy density, 95% charge efficiency versus 80% for lead acid, and requires virtually zero maintenance.

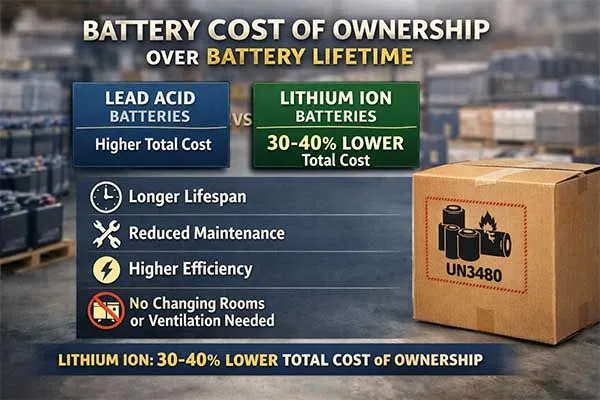

While initial costs run 2-3 times higher, total cost of ownership typically favors lithium ion by 30-40% over the battery’s lifetime due to reduced replacement frequency and operational expenses.

The batteries you choose directly impact operational costs, equipment downtime, and long-term profitability. Many industrial facilities still rely on outdated lead acid technology, accepting frequent maintenance, shorter lifespans, and higher total costs as unavoidable. But modern lithium ion alternatives challenge these assumptions completely.

Understanding these differences helps you make informed decisions that align with your operational goals and budget constraints. Let’s examine the technical specifications, real-world performance, and economic factors that separate these two battery chemistries.

Table of Contents

- How Do Lead Acid and Lithium Ion Batteries Work Differently?

- What Are the Key Performance Differences in Energy Density and Power Output?

- How Do Lifespan and Cycle Life Compare Between These Technologies?

- What Are the Real Costs: Initial Investment vs Total Ownership?

- Which Battery Type Performs Better in Industrial Applications?

- How Do Maintenance Requirements Differ?

- What Safety Considerations Should You Know?

- Which Battery Is Better for Energy Storage Systems?

How Do Lead Acid and Lithium Ion Batteries Work Differently?

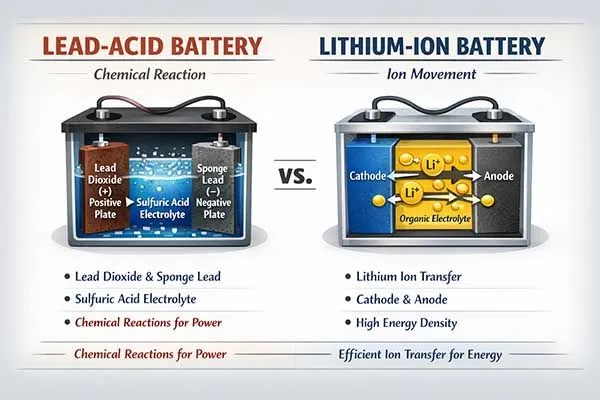

Lead acid batteries use lead plates submerged in sulfuric acid electrolyte, generating electricity through chemical reactions between lead dioxide (positive plate), sponge lead (negative plate), and sulfuric acid.

Lithium ion batteries store energy by moving lithium ions between a cathode and anode through an organic electrolyte, offering higher efficiency and energy density through faster ion movement and reversible electrochemical reactions.

The fundamental chemistry creates vastly different performance characteristics.

Lead acid technology dates back to 1859, relying on heavy lead plates that undergo physical changes during charge and discharge cycles. These reactions create lead sulfate crystals that gradually reduce battery capacity over time.

The sulfuric acid electrolyte also requires periodic maintenance in flooded designs, and even sealed variants experience gradual degradation.

Basic Operating Principles

Lithium ion batteries represent a completely different approach to energy storage. Instead of heavy metal plates, they use lightweight metal oxide cathodes and carbon anodes.

When you discharge the battery, lithium ions flow from the anode through the electrolyte to the cathode, creating electrical current. During charging, these ions move back to the anode, ready for the next cycle.

The difference between lead acid battery and lithium ion battery becomes obvious in their charge acceptance rates.

Lead acid batteries slow down significantly as they approach full charge, often taking 8-12 hours for a complete charge cycle. The lithium battery vs lead acid battery comparison shows lithium accepting charge at much higher rates throughout the entire charging process, with many systems reaching 80% capacity in just 1-2 hours.

| Characteristic | Lead Acid | Lithium Ion |

|---|---|---|

| Operating Voltage | 2.0V per cell | 3.6-3.7V per cell |

| Charge Efficiency | 80% | 95%+ |

| Self-Discharge Rate | 5-15% per month | 1-3% per month |

| Operating Temperature | -20°C to 50°C | -20°C to 60°C |

| Charge Time (0-100%) | 8-12 hours | 1-3 hours |

Chemical Reaction Efficiency

The electrochemical efficiency differs substantially. Lead acid systems waste about 20% of input energy as heat during charging, achieving roughly 80% round-trip efficiency.

Lithium ion battery vs lead acid systems achieve 95% or higher efficiency, meaning less energy waste and lower operating costs. This five-percentage-point advantage compounds over thousands of cycles.

Temperature affects these chemistries differently too. Lead acid batteries lose capacity rapidly in cold conditions and suffer accelerated degradation in heat. The lithium ion battery vs lead acid battery temperature tolerance shows lithium maintaining consistent performance across wider temperature ranges, though both technologies benefit from climate-controlled environments in critical applications.

Need Expert Guidance on Battery Selection?

Our engineering team analyzes your specific application requirements.

What Are the Key Performance Differences in Energy Density and Power Output?

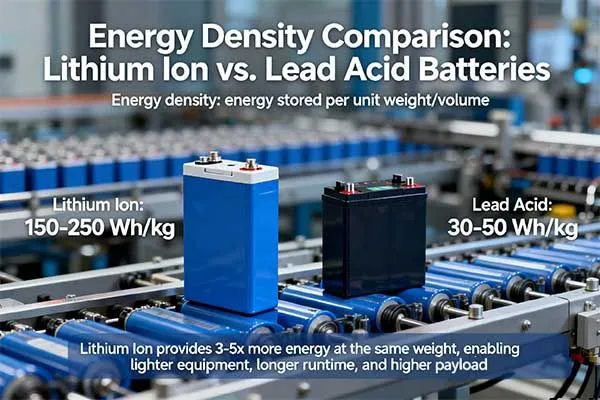

Energy density represents the amount of energy stored per unit weight or volume.

Lithium ion batteries deliver 150-250 Wh/kg compared to lead acid’s 30-50 Wh/kg, providing 3-5 times more energy in the same weight. This advantage translates to lighter equipment, extended runtime, or increased payload capacity in vehicles and portable applications.

The practical impact shows up immediately in real-world applications. A forklift using a 1,000-pound lead acid battery pack could achieve the same runtime with a 200-300 pound lithium pack.

This weight reduction improves vehicle handling, reduces floor loading, and potentially allows higher payload capacity without exceeding vehicle weight ratings.

Volumetric Energy Density Matters Too

Beyond weight considerations, space efficiency plays a crucial role in many applications. The energy density of lithium ion batteries reaches 250-693 Wh/L compared to lead acid’s 60-110 Wh/L.

When you design battery compartments or retrofit existing equipment, this volumetric advantage often determines whether a conversion is even possible.

Power density describes how quickly a battery can deliver its stored energy. Lithium vs lead acid batteries show dramatic differences here.

Lithium ion cells handle discharge rates of 1C to 5C continuously (draining the full capacity in 12-60 minutes) without significant voltage drop or damage. Lead acid batteries typically limit to 0.2C to 0.5C continuous discharge, and pushing beyond these rates drastically shortens lifespan.

| Performance Metric | Lead Acid | Lithium Ion |

|---|---|---|

| Gravimetric Energy Density | 30-50 Wh/kg | 150-250 Wh/kg |

| Volumetric Energy Density | 60-110 Wh/L | 250-693 Wh/L |

| Usable DoD (for optimal life) | 50% | 80-90% |

| Continuous Discharge Rate | 0.2-0.5C | 1-5C |

| Peak Discharge Rate | 1-2C (brief) | 10C+ (brief) |

Peak Power Capabilities

The lead acid vs lithium ion comparison becomes critical in applications requiring high instantaneous power. Electric vehicle acceleration, power tool bursts, and grid stabilization all demand rapid energy delivery.

Lithium ion chemistry provides 3-4 times the power density of lead acid, enabling better performance without oversizing the battery pack. The lithium battery vs lead acid battery power delivery advantage makes lithium ideal for demanding applications.

Tips

Lithium ion batteries support higher peak power output with lower internal resistance, making them suitable for dynamic load conditions.

Depth of discharge (DoD) significantly affects usable capacity. Lead acid batteries should stay above 50% state of charge to maximize lifespan, meaning you can only use half the rated capacity regularly.

The lithium ion vs lead acid practical capacity shows lithium safely operating down to 20% or even 10% DoD, effectively doubling usable energy from the same nameplate capacity. This lead acid battery vs lithium usable capacity difference is substantial in real-world applications.

The energy density advantage explains why electric vehicles, portable power tools, and mobile applications increasingly favor lithium technology despite higher initial costs.

Ready to Upgrade Your Battery System?

Calculate your potential performance improvements with our technical team.

How Do Lifespan and Cycle Life Compare Between These Technologies?

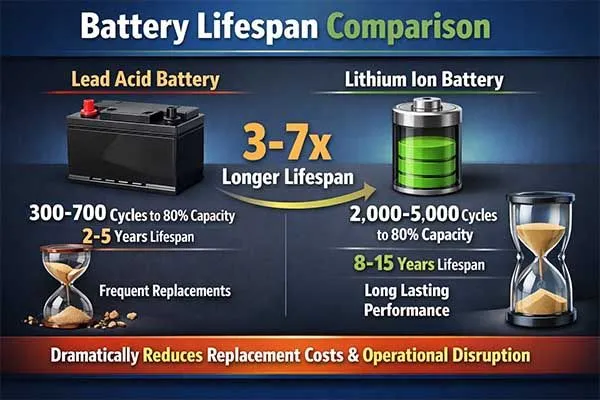

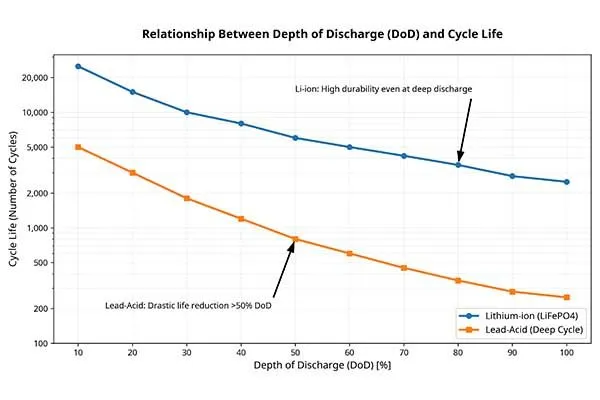

Lead acid batteries typically deliver 300-700 charge cycles before capacity drops to 80% of original rating, translating to 2-5 years in daily-use applications. Lithium ion batteries provide 2,000-5,000 cycles to 80% capacity, lasting 8-15 years under similar conditions.

This 3-7 times longer lithium ion vs lead acid battery lifespan dramatically reduces replacement costs and operational disruption.

The cycle life difference stems from fundamental chemistry. Each charge-discharge cycle physically degrades lead acid plates through sulfation, active material shedding, and grid corrosion. Even proper maintenance only slows this inevitable process.

Calendar aging also affects lead acid significantly, with batteries losing capacity even when stored unused. The lead acid vs lithium ion battery degradation pattern differs substantially between these technologies.

Factors Affecting Battery Longevity

Depth of discharge dramatically impacts cycle life for both chemistries, but affects lead acid more severely. Operating lead acid batteries at 50% DoD might yield 700 cycles, but regular 80% DoD operation drops this to 200-300 cycles.

The lead acid battery vs lithium ion comparison shows lithium maintaining 3,000+ cycles even at 80% DoD, with minimal penalty for deep discharge operation.

Temperature accelerates degradation in both technologies. Lead acid batteries lose roughly 50% of their lifespan for every 15°F (8°C) temperature increase above 77°F (25°C). Hot warehouses or outdoor installations can cut a five-year lead acid battery life to 2-3 years.

Lithium technology handles heat better but still benefits from thermal management in extreme conditions. The lead acid battery vs lithium ion temperature tolerance affects long-term performance significantly.

Real-World Longevity Expectations

The lead acid battery vs lithium battery calculation changes dramatically when you factor in replacement cycles. A facility running forklifts on two shifts daily might replace lead acid batteries every 2-3 years versus 10-12 years for lithium equivalents.

This means purchasing and installing 4-5 lead acid battery sets versus one lithium system over a decade. The lead acid vs lithium ion replacement frequency has major budget implications.

Partial state of charge (PSoC) operation kills lead acid batteries quickly but doesn’t significantly harm lithium systems. Applications involving frequent partial charges between shifts or opportunity charging favor lithium ion vs lead acid dramatically.

Lead acid batteries operated in PSoC mode often fail within 6-12 months due to rapid sulfation. The lead acid battery vs lithium battery PSoC tolerance makes lithium ideal for modern operations.

| Lifespan Factor | Lead Acid | Lithium Ion |

|---|---|---|

| Cycle Life (80% DoD) | 300-500 cycles | 3,000-5,000 cycles |

| Cycle Life (50% DoD) | 500-700 cycles | 5,000-8,000 cycles |

| Calendar Life | 3-5 years | 10-15 years |

| Temperature Impact | High (50% reduction per 8°C rise) | Moderate (20% reduction per 8°C rise) |

| PSoC Operation Tolerance | Very poor | Excellent |

As a lithium ion battery manufacturer, we’ve documented real-world performance across thousands of installations.

One European logistics center retrofitted 50 forklifts from lead acid to our lithium systems. After three years, these batteries still maintain 92% of original capacity, while their previous lead acid batteries required replacement every 18-24 months under the same duty cycle.

Our Chief Engineer Jack Song has developed battery management systems specifically optimized for extended lifespan in industrial applications. If you need guidance on maximizing battery longevity for your specific use case, reach out to our engineering team.

Calculate Your Long-Term Battery Investment

See how cycle life impacts your total cost of ownership.

What Are the Real Costs: Initial Investment vs Total Ownership?

Lead acid batteries cost $100-200 per kWh installed, while lithium ion systems run $400-800 per kWh initially.

However, lithium ion vs lead acid battery cost comparison over the battery lifetime shows lithium achieving 30-40% lower total cost of ownership due to longer lifespan, reduced maintenance, higher efficiency, and eliminated infrastructure requirements like battery changing rooms and ventilation systems.

The upfront price difference seems significant and often stops procurement discussions before deeper analysis occurs. A 20 kWh forklift battery might cost $2,000-3,000 in lead acid versus $8,000-12,000 in lithium. But this initial figure ignores replacement frequency, labor costs, energy consumption, and opportunity costs from downtime.

Hidden Costs in Lead Acid Systems

Lead acid operations carry substantial hidden expenses. Flooded batteries require watering every 1-2 weeks, consuming 10-20 minutes of labor per battery.

For example, facilities running 50 forklifts spend 40-80 hours monthly just on battery maintenance. At $25-35 per hour labor rates, this adds $12,000-28,000 annually in direct maintenance costs alone.

Battery changing infrastructure represents another significant investment. Multi-shift operations need 2-3 battery packs per vehicle to maintain continuous operation.

A 50-vehicle fleet requires 100-150 batteries, battery changing equipment, charging stations, and dedicated floor space. This infrastructure investment often equals or exceeds the battery cost itself.

Energy Cost Analysis

Charging efficiency differences compound over years of operation. A 20 kWh battery charged 250 times annually consumes 6,250 kWh with 80% lead acid efficiency versus 5,260 kWh with 95% lithium efficiency. At $0.12 per kWh, this 990 kWh difference costs roughly $120 per battery annually, or $6,000 across a 50-vehicle fleet.

Key Takeaway

Higher charging efficiency enables lithium ion batteries to reduce long-term energy consumption and operating costs.

The lithium ion vs lead acid for industrial equipment financial analysis must include productivity factors too. Lead acid batteries require changing every 6-8 hours, consuming 15-20 minutes of vehicle downtime per change.

Lithium systems use opportunity charging during breaks, eliminating battery changing completely. This recovered productivity translates to substantial value in high-utilization operations.

| Cost Factor (per kWh) | Lead Acid | Lithium Ion |

|---|---|---|

| Initial Purchase | $100-200 | $400-800 |

| Installation | $20-40 | $40-80 |

| Annual Maintenance | $15-30 | $2-5 |

| Energy Cost (per cycle at $0.12/kWh) | $0.15 | $0.13 |

| Replacement Frequency | Every 2-4 years | Every 10-15 years |

| 10-Year Total Cost | $400-800 | $450-900 |

At Long Sing Energy, we worked with a European logistics park that needed to upgrade their aging forklift fleet. Our team provided sample batteries for field testing, allowing them to validate performance claims before committing to full fleet conversion.

After analyzing their three-shift operation, we designed a lithium system that eliminated their battery changing room, freed up 400 square feet of valuable warehouse space, and reduced their spare battery inventory from 100 units to 50.

Real-World ROI Timeline

The break-even point typically occurs within 3-5 years for high-utilization applications. That European logistics park now saves €120,000 annually through eliminated electricity waste, reduced maintenance labor, and improved operational efficiency.

Their initial investment premium paid back in under four years, and they expect 8-10 additional years of service from the lithium systems.

Single-shift operations with lower utilization may see longer payback periods, but the total cost advantage still favors lithium in most scenarios. The key is running a complete analysis specific to your operational patterns.

Need a Custom Cost Analysis?

Our team models your specific operational costs and ROI timeline.

Which Battery Type Performs Better in Industrial Applications?

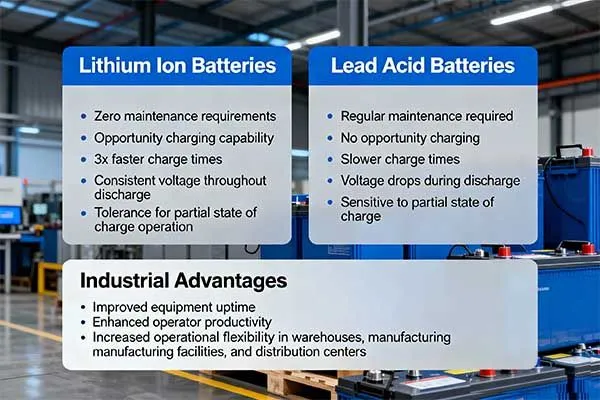

Lithium ion batteries outperform lead acid in virtually all industrial metrics: zero maintenance requirements, opportunity charging capability, 3x faster charge times, consistent voltage throughout discharge, and tolerance for partial state of charge operation.

These advantages translate to improved equipment uptime, operator productivity, and operational flexibility in warehouses, manufacturing facilities, and distribution centers.

Industrial environments demand reliable, consistent power delivery. Forklifts, automated guided vehicles, scissor lifts, and floor scrubbers represent the backbone of material handling operations. Battery performance directly impacts throughput, labor efficiency, and operational costs.

Forklift and Material Handling Applications

The lead acid vs lithium ion battery comparison becomes most dramatic in multi-shift forklift operations.

Traditional lead acid systems require battery changing after 5-7 hours of operation, creating workflow interruptions and requiring dedicated changing stations. Operators spend time locating charged batteries, performing exchanges, and moving depleted units to charging areas.

Lithium systems enable opportunity charging during existing breaks and shift changes.

A forklift can charge for 15-20 minutes during lunch breaks and shift transitions, maintaining charge throughout extended operations. This eliminates battery changing infrastructure, reduces spare battery inventory, and reclaims valuable warehouse space previously dedicated to battery rooms.

Voltage Stability and Performance Consistency

Lead acid batteries exhibit significant voltage sag as they discharge, with performance dropping noticeably below 50% state of charge. Forklift operators experience reduced lift capacity, slower travel speeds, and decreased hydraulic response as batteries deplete.

The lithium battery vs lead acid battery voltage curve shows lithium maintaining consistent output voltage until nearly fully discharged, providing uniform equipment performance throughout the shift.

This consistent performance eliminates the productivity decline that occurs in lead acid operations. Operators don’t experience gradually deteriorating equipment response, maintaining the same lift speeds and cycle times whether the battery is 90% or 20% charged.

| Industrial Performance Factor | Lead Acid | Lithium Ion |

|---|---|---|

| Charge Time (0-80%) | 6-8 hours | 1-2 hours |

| Battery Changes per Day (2-shift) | 1-2 times | Zero (opportunity charging) |

| Voltage Consistency | Poor (drops significantly) | Excellent (flat curve) |

| Maintenance Downtime | 2-4 hours/month | <30 minutes/month |

| Backup Battery Need | 2-3x fleet size | 1x fleet size |

AGV and Automated Equipment Integration

Automated guided vehicles and robotic systems particularly benefit from lithium technology. These systems often operate 24/7 with scheduled charging windows.

The lithium ion vs lead acid fast charging capability means AGVs can fully recharge during short maintenance windows or between task assignments, maintaining higher fleet utilization.

Battery management system integration also favors lithium solutions. Modern lithium batteries provide detailed state-of-charge data, health metrics, and predictive maintenance alerts through digital communication protocols.

This data integration helps optimize fleet management, schedule maintenance proactively, and prevent unexpected failures.

The eliminated downtime and improved operational flexibility justify the investment premium for most industrial applications, particularly in facilities operating multiple shifts or requiring high equipment availability.

Optimize Your Material Handling Operations

See how lithium systems improve your warehouse efficiency.

How Do Maintenance Requirements Differ?

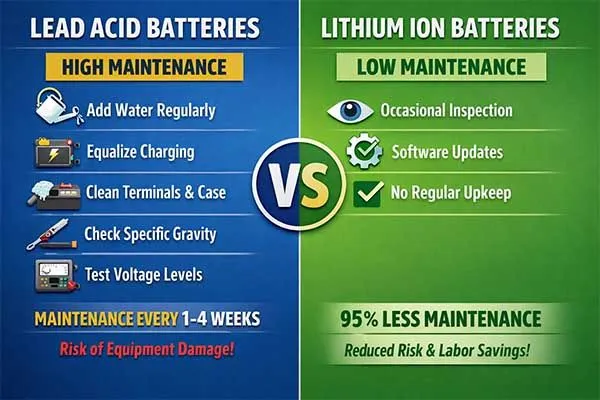

Lead acid batteries require regular watering (flooded types), equalization charging, cleaning of terminals and cases, specific gravity testing, and voltage checks every 1-4 weeks depending on usage.

Lithium ion batteries need virtually zero routine maintenance beyond occasional visual inspection and software updates, eliminating 95% of maintenance labor while reducing the risk of equipment damage from neglected maintenance.

The maintenance burden represents one of the most significant operational differences between these technologies. Lead acid batteries demand consistent attention to maintain performance and longevity, while lithium systems operate essentially maintenance-free for their entire service life.

Lead Acid Maintenance Requirements

Flooded lead acid batteries consume water during normal operation as charging causes electrolysis, breaking down water into hydrogen and oxygen gas.

Facilities must establish regular watering schedules, typically adding distilled water every 5-10 cycles depending on usage intensity. Each battery requires 5-15 minutes of labor for proper watering, and missing these cycles causes permanent capacity loss from plate exposure.

Equalization charging combats sulfation but requires specialized procedures. Operators must monitor individual cell voltages, ensure adequate ventilation during the extended high-voltage charging process, and understand when equalization is needed. Improper equalization wastes time and energy, while neglecting it shortens battery life.

Terminal Corrosion and Cleaning

Battery terminals corrode over time from acid fumes and environmental exposure. This corrosion increases resistance, reduces charging efficiency, and can cause intermittent connectivity issues.

Maintenance schedules should include quarterly terminal cleaning, application of protective coatings, and inspection of cable connections.

The specific gravity testing provides insight into battery health but requires specialized equipment and trained personnel. Maintenance staff must draw electrolyte samples from each cell, measure density with a hydrometer, and interpret results to assess battery condition. This testing should occur monthly for critical applications but often gets deferred in busy operations.

Lithium Battery Simplicity

The lithium ion battery vs lead acid maintenance comparison couldn’t be more different.

Lithium systems use sealed cells that never require watering, produce no corrosive fumes, and include integrated battery management systems that automatically balance cells and protect against overcharge or overdischarge conditions.

Quarterly visual inspections check for physical damage, verify clean terminals, and ensure proper mounting security. Annual firmware updates from the manufacturer may add features or optimize performance, typically completed remotely through connected systems. That’s essentially the complete maintenance requirement.

This dramatic reduction in maintenance labor translates directly to cost savings.

A facility maintaining 50 lead acid batteries might spend 40-60 hours monthly on battery maintenance. Switching to lithium reduces this to perhaps 2-3 hours monthly for basic visual checks, freeing maintenance staff for more value-added activities.

| Maintenance Task | Lead Acid Frequency | Lithium Ion Frequency |

|---|---|---|

| Watering | Every 5-10 cycles | Never |

| Equalization Charge | Monthly | Never |

| Specific Gravity Testing | Monthly | Never |

| Terminal Cleaning | Quarterly | Annually |

| Visual Inspection | Weekly | Quarterly |

| Software/Firmware Updates | N/A | Annually |

| Labor Hours (per 50 batteries/month) | 40-60 hours | 2-3 hours |

The reduced maintenance burden also decreases the risk of premature failure from neglected maintenance. Busy facilities often defer lead acid maintenance during peak seasons, causing permanent capacity loss and shortened lifespan. Lithium systems suffer no performance penalty from this operational reality.

Reduce Your Maintenance Overhead

Calculate maintenance labor savings with lithium technology.

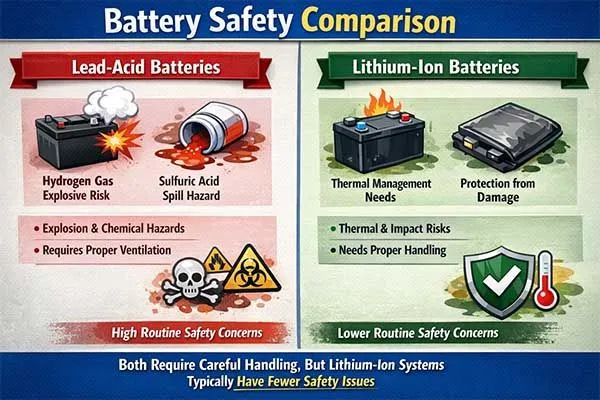

What Safety Considerations Should You Know?

Lead acid batteries produce hydrogen gas during charging, creating explosion risks without proper ventilation. The sulfuric acid electrolyte causes severe burns and environmental contamination if spilled.

Lithium ion batteries eliminate these hazards but require proper thermal management and protection against physical damage. Both technologies need appropriate handling procedures, though lithium systems generally present fewer routine safety concerns.

Safety protocols directly impact operational costs and workplace risks. Understanding the specific hazards of each technology helps facilities implement appropriate safeguards and training programs.

Lead Acid Safety Hazards

Hydrogen gas generation represents the primary explosion risk in lead acid battery operations. During charging, electrolysis produces hydrogen and oxygen gases that can form explosive mixtures if concentrated.

The lead acid battery vs lithium battery safety comparison shows lead acid requiring dedicated battery charging rooms with ventilation systems providing at least six air changes per hour to safely disperse gases.

Regulations typically require battery rooms to be classified as Class I, Division 2 hazardous locations under the National Electric Code, mandating explosion-proof electrical fixtures and equipment. This classification requirement adds substantial cost to facility design and limits installation flexibility.

Tips

The National Electrical Code (NEC) is the US’ primary safety standard for electrical design, installation, and inspection. Formally known as NFPA 70, it’s published by the National Fire Protection Association (NFPA) and updated on a 3-year cycle.

Chemical Exposure Risks

Sulfuric acid electrolyte presents serious burn hazards. Battery maintenance and changing operations risk acid splashes to skin, eyes, and clothing.

Facilities must provide emergency eyewash stations, safety showers, proper personal protective equipment, and spill containment materials. OSHA regulations mandate specific training for employees working with lead acid batteries.

Disposal and recycling also create environmental concerns. Lead is a toxic heavy metal requiring careful handling, and improper disposal causes serious environmental contamination. While battery recycling programs exist, they represent an additional operational burden and cost.

Lithium Ion Safety Considerations

The lithium vs lead acid safety profile differs significantly.

Lithium batteries eliminate hydrogen generation, corrosive electrolyte, and heavy metal content. However, they introduce different considerations around thermal management and physical protection.

Thermal runaway represents the primary lithium safety concern. While rare in quality systems, physical damage, manufacturing defects, or improper charging can cause internal short circuits leading to rapid temperature increase.

Proper battery management systems include multiple layers of protection against overcharge, overdischarge, and thermal events.

At Long Sing Energy, we incorporate multilayer safety features in our industrial lithium batteries. Each cell includes thermal monitoring, current limiting, and pressure relief mechanisms.

The battery management system continuously monitors hundreds of parameters, disconnecting the battery if any values exceed safe operating ranges. Our systems have accumulated millions of operating hours across industrial applications without thermal incidents.

Ensure Compliant Battery Safety

Our team reviews your facility safety requirements and protocols.

Transportation and Handling Requirements

Transportation regulations differ substantially between these technologies. Lead acid batteries ship as Class 8 corrosive materials, requiring hazmat paperwork and handling procedures.

Lithium ion batteries fall under Class 9 miscellaneous hazardous materials with specific UN testing and documentation requirements, though many industrial battery packs qualify for testing exemptions.

| Safety Factor | Lead Acid | Lithium Ion |

|---|---|---|

| Hydrogen Gas Risk | High (requires ventilation) | None |

| Chemical Burn Risk | High (sulfuric acid) | Low (sealed cells) |

| Thermal Runaway Risk | Very Low | Low (with proper BMS) |

| Environmental Contamination Risk | High (lead, acid) | Low |

| Ventilation Requirements | Mandatory | Standard building ventilation |

| Hazmat Classification | Class 8 (Corrosive) | Class 9 (Miscellaneous) |

Both technologies require appropriate training, handling procedures, and emergency response protocols. The key difference lies in routine operational hazards versus rare but serious events.

Lead acid presents continuous chemical and gas exposure risks during normal operation, while lithium systems operate safely under normal conditions but require proper protection against abuse conditions.

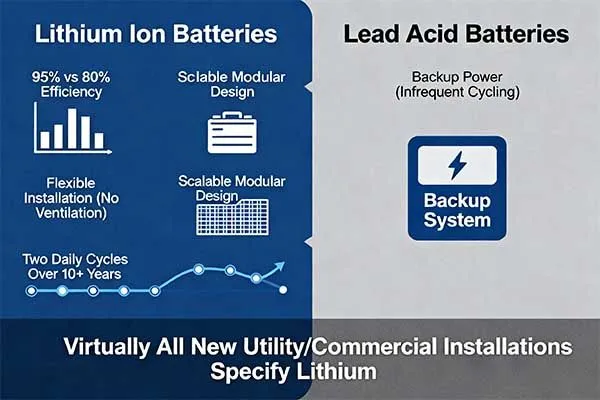

Which Battery Is Better for Energy Storage Systems?

Lithium ion batteries dominate grid-scale and commercial energy storage due to superior efficiency (95% vs 80%), flexible installation without ventilation requirements, scalable modular design, and longer cycle life enabling two daily charge-discharge cycles over 10+ year lifespans.

While lead acid remains viable for backup power applications with infrequent cycling, virtually all new utility and commercial installations specify lithium technology.

Energy storage systems serve diverse applications from residential solar integration to utility-scale grid stabilization. The performance requirements differ substantially from motive power applications, emphasizing cycle efficiency, response time, and installation flexibility.

Grid-Scale Storage Requirements

Utility-scale energy storage demands rapid response to grid signals, high cycle efficiency to maximize revenue from arbitrage operations, and long cycle life to justify capital investment.

The lead acid battery vs lithium ion battery efficiency difference becomes economically critical when cycling daily across 3,000-5,000 lifetime cycles.

A 10 MWh storage system cycling once daily at 95% efficiency delivers 9.5 MWh to the grid per cycle. The same system at 80% efficiency delivers only 8.0 MWh, losing 1.5 MWh daily.

Over 300 annual cycles, this 450 MWh difference represents $45,000-90,000 in lost revenue at typical electricity arbitrage margins.

Commercial and Industrial Applications

Commercial facilities increasingly install energy storage for demand charge reduction, backup power, and solar integration. These applications require systems that fit within existing electrical rooms, operate reliably for 10-15 years, and require minimal maintenance attention.

The lithium ion vs lead acid footprint comparison favors lithium dramatically. A 500 kWh commercial storage system might occupy 200-300 square feet with lead acid batteries versus 80-120 square feet with lithium.

The lithium system also eliminates the need for dedicated ventilation, simplifying installation in existing buildings.

Response Time and Power Quality

Grid support applications like frequency regulation require sub-second response times to power commands.

Lithium technology responds essentially instantaneously to load changes, making it ideal for these high-value applications. Lead acid batteries respond more slowly due to electrochemical limitations, restricting them to less demanding applications.

Power quality applications benefit from lithium’s ability to handle high charge and discharge rates simultaneously. A lithium system can absorb regenerative braking energy while simultaneously supplying building loads, something difficult to achieve with lead acid technology.

| Energy Storage Factor | Lead Acid | Lithium Ion |

|---|---|---|

| Round-Trip Efficiency | 80% | 95%+ |

| Response Time | 1-5 seconds | <1 second |

| Daily Cycling Suitability | Poor (500 cycles) | Excellent (5,000+ cycles) |

| Space Efficiency | 60-110 Wh/L | 250-693 Wh/L |

| Installation Flexibility | Requires ventilation | Standard locations |

| Depth of Discharge | 50% recommended | 80-90% standard |

Backup Power Considerations

Uninterruptible power supply (UPS) applications represent one area where lead acid maintains some cost advantages. These systems cycle infrequently, perhaps a few times yearly during power outages.

The difference between lead acid battery and lithium ion battery becomes less significant when cycling only 20-50 times over a 10-year period rather than thousands of cycles.

However, even backup power applications increasingly favor lithium for the space savings, faster recharge after outages, and elimination of maintenance requirements. Data centers and critical facilities particularly value the reliability and predictability of lithium systems.

The economic analysis almost always favors lithium for energy storage applications involving frequent cycling. Only low-utilization backup power scenarios show potential cost advantages for lead acid, and even these are diminishing as lithium prices continue declining.

Design Your Energy Storage System

Our engineers specify optimal battery configuration for your application.

Conclusion

Lithium-ion batteries offer superior long-term value over lead-acid for most industrial, commercial, and energy storage applications due to longer lifespan, higher efficiency, zero maintenance, and greater flexibility.

They deliver 3–5× the energy density, 95% charging efficiency (vs. 80% for lead-acid), and 3,000–5,000 cycles compared to just 300–700.

These advantages translate to 30–40% lower total cost of ownership despite a higher initial price.

Lead-acid remains suitable only for low-use backup scenarios, while lithium-ion is now the default choice for new installations thanks to falling costs and proven reliability.

Contact Long Sing Energy’s engineering team—led by Chief Engineer Jack Song—to evaluate your needs and calculate your potential ROI with lithium technology.

Frequently Asked Questions

Click to explore more information about Lead Acid vs Lithium ion Battery

Q: Is lithium-ion better than lead-acid?

A: Generally, yes. In industrial and high-use settings, lithium-ion outperforms lead-acid by offering higher energy density, faster charging (1-2 hours vs. 6-8 hours), and a maintenance-free design that eliminates the need for watering or equalizing charges.

Q: What is the biggest disadvantage of a lithium-ion battery?

A: The most significant disadvantage is the higher initial upfront cost. While lithium-ion batteries offer a lower total cost of ownership over their lifespan, the initial purchase price can be 2 to 3 times higher than a comparable lead-acid battery.

Q: What lasts longer, lead-acid or lithium?

A: Lithium-ion batteries last significantly longer. A typical lithium battery can handle 3,000 to 5,000+ charge cycles, whereas a lead-acid battery usually lasts only 500 to 1,500 cycles before its capacity drops significantly.

Q: Can I just replace a lead-acid battery with lithium?

A: Often yes, but with caveats. While “drop-in” replacements exist, you must ensure the charger is compatible with lithium charging profiles and that the voltage and physical dimensions fit your equipment’s specific requirements.

Q: Which is safer, a lithium or lead-acid battery?

A: Both are safe when handled correctly. Lead-acid batteries pose risks involving acid spills and explosive gas during charging. Lithium-ion batteries (specifically LiFePO4) are incredibly stable but require a Battery Management System (BMS) to prevent overheating or overcharging.