Energy Density of Lithium-Ion Batteries determines how much power you can store per unit weight or volume, directly influencing runtime, device size, and overall system efficiency across real-world applications.

The energy density of lithium-ion batteries measures how much energy a battery stores relative to its weight (Wh/kg) or volume (Wh/L). Gravimetric energy density (Wh/kg) indicates energy per kilogram, while volumetric energy density (Wh/L) shows energy per liter.

Modern lithium-ion batteries achieve 150-300 Wh/kg and 250-700 Wh/L, depending on chemistry and design. Understanding both metrics helps you select batteries that optimize space and weight for your specific application.

Selecting the right battery can feel overwhelming when you’re facing tight space limits and strict weight requirements. You need batteries that deliver maximum power without adding bulk or weight to your design. The wrong choice means compromised performance, shorter runtime, or complete project failure.

This guide breaks down the difference between these two critical metrics and shows you how to choose the right balance for your application. We’ll examine real-world scenarios and provide practical selection criteria.

Table of Contents

- What Is Energy Density and Why Does It Matter for Battery Performance?

- How Do Gravimetric (Wh/kg) and Volumetric (Wh/L) Energy Density Differ?

- What Factors Influence the Energy Density of Lithium-Ion Batteries?

- Which Battery Chemistry Offers the Highest Energy Density?

- How Does Energy Density Compare to Power Density in Battery Selection?

What Is Energy Density and Why Does It Matter for Battery Performance?

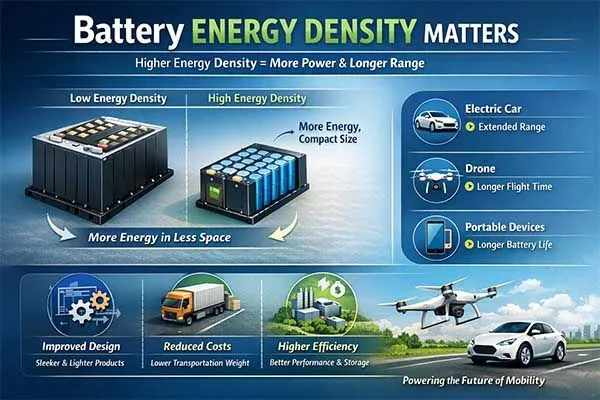

Battery energy density defines the amount of electrical energy stored in a given mass or volume of battery. Higher energy density means longer runtime and extended range for electric vehicles, portable electronics, and energy storage systems.

This metric directly impacts product design, transportation costs, and system efficiency. For applications like unmanned aerial vehicles and electric mobility, maximizing energy density of batteries is essential for competitive performance.

Energy density serves as the foundation for battery selection across industries. When you design an electric vehicle, you face a constant trade-off between battery weight and driving range.

A battery with low lithium ion energy density forces you to add more cells, which increases vehicle weight and reduces efficiency. The same principle applies to power tools, where users demand lightweight designs without sacrificing runtime.

The importance of this metric extends beyond consumer applications. In grid-scale energy storage systems, higher energy density of lithium ion battery units reduces the physical footprint of installations. This translates to lower real estate costs and simplified deployment in urban areas.

At Long Sing Energy, we’ve worked with a major U.S. energy storage company to increase their system’s energy density by 15% through optimized cell design and improved cell-to-pack efficiency.

Energy Density Measurement Types

| Metric Type | Measurement Unit | Primary Application Focus | Typical Range |

|---|---|---|---|

| Gravimetric | Wh/kg | Weight-sensitive applications | 150-300 Wh/kg |

| Volumetric | Wh/L | Space-constrained designs | 250-700 Wh/L |

Gravimetric energy density measures energy per unit mass. This metric matters most for applications where weight directly affects performance. Aircraft, drones, and portable devices benefit from high Wh/kg ratings because every gram counts toward payload capacity or user comfort.

When we develop cylindrical battery solutions for unmanned aerial vehicle manufacturers, we prioritize gravimetric density to maximize flight time.

Volumetric energy density measures energy per unit volume. This becomes critical when you have limited space but can tolerate additional weight. Consumer electronics, electric scooters, and compact power tools typically prioritize Wh/L. The prismatic battery format often achieves better volumetric density due to more efficient space utilization compared to cylindrical cells.

Want to Prevent Redesigns and Delays Later?

Let’s consult with a manufacturer like Long Sing Energy before procurement.

The relationship between these two metrics reveals important design characteristics. A battery with excellent gravimetric density might have mediocre volumetric density if it uses lightweight but bulky packaging.

We saw this trade-off clearly when working with a European e-bike manufacturer. They initially wanted maximum Wh/kg for marketing purposes, but their frame geometry limited battery compartment volume.

We switched to a prismatic design that sacrificed 5% gravimetric density but improved volumetric density by 20%, which actually increased their usable capacity.

How Do Gravimetric (Wh/kg) and Volumetric (Wh/L) Energy Density Differ?

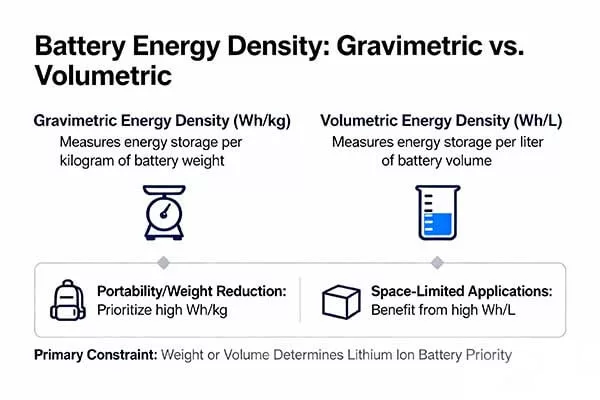

Gravimetric energy density (Wh/kg) measures energy storage per kilogram of battery weight, while volumetric energy density (Wh/L) measures energy storage per liter of battery volume.

Applications prioritizing portability and weight reduction need high Wh/kg, whereas space-limited applications benefit from high Wh/L. The lithium ion battery energy density you prioritize depends on your application’s primary constraint: weight or volume.

The distinction between these metrics becomes clear when you examine battery construction. A battery’s total weight includes active materials (cathode, anode, electrolyte), current collectors, separators, housing, and terminals.

The lithium battery energy density achieved depends on how much of this weight contributes to energy storage versus structural support. Lightweight aluminum housings improve Wh/kg but may reduce Wh/L if they require thicker walls for structural integrity.

Volume calculations must account for dead space between cells, cooling channels, and safety gaps.

A cylindrical cell has inherent gaps when packed together, reducing system-level volumetric density by 20-30% compared to cell-level specifications. Prismatic cells can be packed more tightly, which explains why smartphone manufacturers prefer this format despite slightly lower cell-level performance.

Real-World Applications and Trade-offs

| Application | Primary Constraint | Preferred Metric | Typical Requirement |

|---|---|---|---|

| Electric Vehicles | Weight affects range | Wh/kg | 200+ Wh/kg |

| Smartphones | Thin profile needed | Wh/L | 600+ Wh/L |

| Drones | Flight time limited by weight | Wh/kg | 250+ Wh/kg |

| Power Tools | Handle ergonomics | Both | 180+ Wh/kg, 450+ Wh/L |

| Grid Storage | Installation footprint | Wh/L | 400+ Wh/L |

The battery density you optimize for shapes your entire product strategy. I remember working with a recreational vehicle manufacturer who initially insisted on maximum gravimetric density.

Their RVs had plenty of floor space but needed to stay under highway weight limits. We conducted a detailed analysis comparing NMC and LFP chemistries at different pack configurations. The data showed that a slightly heavier LFP system with better volumetric density actually allowed them to fit more total energy within their space constraints while staying under weight limits.

This type of analysis requires understanding your application’s limiting factor. For light electric vehicles like e-scooters, riders feel every extra kilogram in handling and acceleration. We prioritize li ion energy density in these cases, even if it means using a slightly larger battery compartment.

For stationary energy storage systems, the weight matters less than installation footprint and construction costs. Higher volumetric density reduces building size requirements and simplifies HVAC system design.

Are you optimizing it correctly?

Choosing the right Energy Density of Lithium-Ion Batteries can significantly reduce system weight while extending operating time.

The manufacturing perspective adds another layer. As a lithium ion battery manufacturer, we balance customer requirements against production realities. Higher energy density often requires thinner electrodes, more precise coating processes, and tighter quality control. These factors increase manufacturing costs and reduce yield rates.

When the U.S. energy storage company approached us about improving their system, we started with sampling three different electrode thickness options. The thinnest electrodes offered 8% better li ion battery energy density but showed 15% higher defect rates during testing.

We settled on a middle option that delivered the 15% improvement they needed while maintaining production quality.

What Factors Influence the Energy Density of Lithium-Ion Batteries?

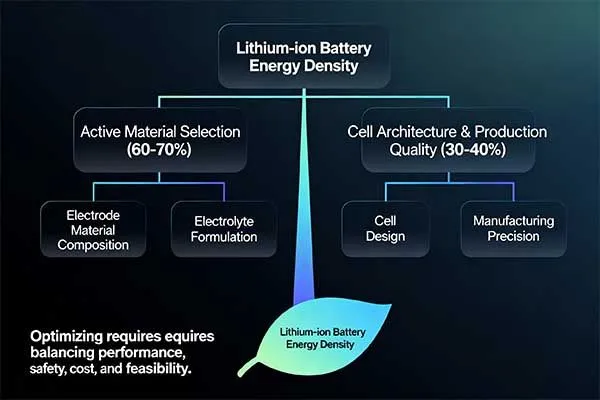

Multiple factors determine the energy density of lithium-ion batteries, including electrode material composition, cell design, electrolyte formulation, and manufacturing precision.

Active material selection accounts for 60-70% of energy density potential, while cell architecture and production quality determine the remaining 30-40%. Optimizing these factors requires balancing performance, safety, cost, and manufacturing feasibility.

Cathode chemistry forms the foundation of battery performance. NMC (Nickel Manganese Cobalt) cathodes deliver high gravimetric and volumetric energy density, making them ideal for electric vehicles and premium applications.

We use NMC811 formulations that achieve 250-280 Wh/kg at the cell level. LFP (Lithium Iron Phosphate) cathodes offer lower energy density but provide better thermal stability and longer cycle life.

For energy storage system applications where safety and longevity matter more than space efficiency, LFP becomes the better choice despite its 30-40% lower energy density.

Anode materials present another optimization opportunity. Standard graphite anodes work well for most applications, but silicon-doped anodes can increase energy density by 15-25%. The challenge lies in managing silicon’s volume expansion during charging, which causes mechanical stress and capacity fade.

Our development team spent six months perfecting a silicon-graphite composite that improves energy density by 12% while maintaining acceptable cycle life. This innovation helped us achieve the energy density improvements for our U.S. storage partner.

Energy Density Manufacturing and Design Optimization

| Factor Category | Optimization Method | Energy Density Impact | Trade-off Consideration |

|---|---|---|---|

| Electrode Loading | Increase active material thickness | +10-15% | Reduced power capability |

| Packaging Efficiency | Thinner housing, optimized geometry | +5-10% | Higher manufacturing cost |

| Cell Format | Large format prismatic cells | +8-12% | Thermal management complexity |

| Electrolyte Volume | Minimize excess electrolyte | +3-5% | Reduced safety margin |

Cell-to-pack efficiency represents a critical but often overlooked factor. The energy density you measure at the cell level differs significantly from pack-level performance.

A cell might achieve 260 Wh/kg, but the complete battery pack with housing, cooling system, and battery management system might only deliver 180 Wh/kg. Improving cell-to-pack efficiency through better mechanical design and thermal management can recover 10-20% of this loss.

Our quality control process directly impacts energy density outcomes. At our facility, incoming quality control (IQC) begins with raw material verification.

We test electrode coating uniformity using laser profilometry with 10-micron resolution. Uneven coating reduces energy density because thin spots limit capacity while thick spots waste active material.

During cell assembly, we maintain humidity below 1% dewpoint to prevent electrolyte degradation. Even small amounts of moisture can reduce energy density by forming inactive lithium compounds.

Tip: Dewpoint is the temperature to which air must be cooled for water vapor to condense into liquid water (dew). The higherdew point means more moisture.It is critical for lithium batteries, electronics, and coating processes under manufacturing.

The sampling and rework process we used for the energy storage project illustrates this attention to detail. We produced initial samples at three different electrode loadings: 2.8, 3.2, and 3.6 mAh/cm².

The highest loading offered best energy density but showed inconsistent performance. After analyzing the coating process, we discovered that our standard drying parameters didn’t fully remove solvent from thicker electrodes.

We adjusted the drying temperature profile and re-coated samples at 3.4 mAh/cm². These revised samples passed all testing and became the basis for production.

Process optimization continues through formation and aging. Formation cycling activates the battery and builds the solid electrolyte interphase (SEI) layer.

We use a multi-stage formation protocol with precise current and voltage control. This adds three days to production time but improves energy density by 3-4% compared to rapid formation. The investment pays off in both performance and long-term reliability.

Design for Performance

Translate energy density requirements into real-world battery performance and safety.

Which Battery Chemistry Offers the Highest Energy Density?

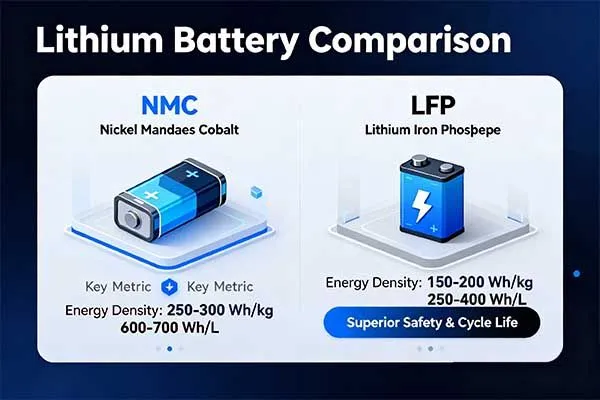

NMC (Nickel Manganese Cobalt) lithium-ion batteries currently offer the highest energy density among commercially available chemistries, achieving 250-300 Wh/kg and 600-700 Wh/L.

LFP (Lithium Iron Phosphate) batteries provide 150-200 Wh/kg and 250-400 Wh/L but offer superior safety and cycle life.

The lithium battery density you need depends on whether your application prioritizes maximum energy storage, cost-effectiveness, safety, or longevity.

Chemistry selection involves more than just looking at energy density specifications. NMC batteries come in several nickel content variants: NMC111, NMC523, NMC622, and NMC811.

The number indicates the ratio of nickel, manganese, and cobalt in the cathode. Higher nickel content increases energy density but reduces thermal stability. NMC811 achieves the best energy density of lithium ion battery cells but requires more sophisticated battery management systems and thermal controls.

The power density of lithium ion battery designs adds another dimension to chemistry selection. NMC batteries typically deliver better power density alongside their energy density advantage. This makes them suitable for applications requiring both high energy storage and rapid discharge capability.

Electric vehicles benefit from this combination because they need both long range and quick acceleration. LFP batteries sacrifice some power density for better thermal stability, making them ideal for energy storage systems where discharge rates are more moderate.

Lithium-Ion Battery Chemistry Specifications

| Chemistry | Energy Density (Wh/kg) | Cycle Life | Safety Rating | Cost Level |

|---|---|---|---|---|

| NMC811 | 250-280 | 1000-2000 cycles | Good | High |

| NMC622 | 230-260 | 1500-2500 cycles | Very Good | Medium-High |

| LFP | 150-200 | 3000-5000 cycles | Excellent | Low-Medium |

| LCO | 200-240 | 500-1000 cycles | Fair | Medium |

Real-world chemistry selection requires understanding total cost of ownership.

LFP batteries cost 20-30% less per kWh than NMC batteries at current market prices. Their longer cycle life means they might last 10-15 years in energy storage applications versus 7-10 years for NMC.

When we analyzed the business case for the U.S. energy storage company, we compared both options over a 15-year deployment period. The analysis showed that LFP systems had lower initial costs but limited expansion potential due to space constraints at their installation sites.

The energy density vs cost trade-off becomes especially important for large-scale deployments. A 10 MWh energy storage system using NMC batteries might require 300 square meters of floor space, while an LFP system might need 450 square meters.

If you’re installing in an urban area where real estate costs $500 per square meter, the extra 150 square meters adds $75,000 to your project. This might justify the premium for higher energy density batteries. In rural areas with cheap land, LFP’s lower material costs make more sense.

We guide customers through this decision by creating detailed comparison models. For the storage project, we built prototypes using both chemistries and tested them under their specific duty cycle.

The NMC system delivered the 15% energy density improvement they wanted and fit within their existing facility footprint. We achieved this through three key changes: switching from NMC622 to NMC811, optimizing electrode thickness, and improving module packaging efficiency.

The production order took eight months from first sample to volume delivery, with two rounds of design refinement based on their field testing feedback.

Custom Energy Solutions

Looking for the highest Wh/L for a compact design? Let us build the ideal lithium-ion configuration for your project.

How Does Energy Density Compare to Power Density in Battery Selection?

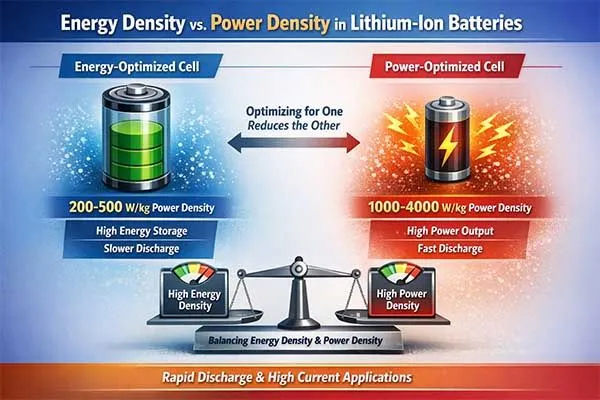

Energy density measures total energy storage capacity, while power density indicates how quickly a battery can deliver that energy.

The power density of lithium ion battery systems ranges from 200-500 W/kg for energy-optimized cells to 1000-4000 W/kg for power-optimized designs. Applications requiring rapid discharge or high current draw must balance energy density with adequate lithium ion power density, as optimizing for one typically reduces the other.

The relationship between these metrics follows from basic electrochemistry. Batteries store energy through chemical reactions that move lithium ions between electrodes.

Energy density depends on how much lithium you can store in each electrode. Power density depends on how fast those ions can move. Thick electrodes store more lithium but create longer ion diffusion paths, reducing power capability. Thin electrodes allow faster ion movement but store less total energy.

This trade-off shapes battery design strategy. Power tools need high power density to deliver strong torque during use. We design these batteries with thinner electrodes, higher porosity, and more conductive additives.

This sacrifices 15-20% energy density compared to energy-optimized designs but delivers 2-3x better power performance. For energy storage systems, the discharge rates are much lower, so we can use thicker electrodes that maximize energy storage.

Energy vs Power Density Trade-offs

| Design Priority | Electrode Thickness | Typical Energy Density | Typical Power Density |

|---|---|---|---|

| Energy Optimized | 60-100 μm | 240-280 Wh/kg | 200-400 W/kg |

| Balanced Design | 40-60 μm | 200-240 Wh/kg | 600-1000 W/kg |

| Power Optimized | 20-40 μm | 150-200 Wh/kg | 1500-3000 W/kg |

Application requirements determine where you fall on this spectrum. Electric mobility applications like e-bikes and light electric vehicles need moderate power for acceleration combined with good energy density for range.

We design these batteries with 50-60 μm electrode thickness, achieving around 220-240 Wh/kg with 800-1200 W/kg power capability. This balances the daily commuting range needs with acceptable acceleration performance.

Understanding your duty cycle helps optimize this balance.

A delivery van that operates in stop-and-go traffic needs different power density than a highway-cruising truck. The van accelerates frequently from stops, requiring higher lithium battery power density.

The truck maintains steady speeds, benefiting more from maximum energy density for extended range. We conduct detailed duty cycle analysis to match battery specifications to real-world usage patterns.

The quality control process must verify both energy and power performance. Our IQC testing includes rate capability tests that measure capacity retention at different discharge rates. A good energy-optimized cell should retain 90% capacity at 0.5C discharge and 80% capacity at 1C discharge.

Power-optimized cells should maintain 85% capacity at 2C and 70% at 5C. Cells that fail these criteria get rejected regardless of their rated specifications.

Optimize Your System Performance

High energy density shouldn’t mean high risk—discover how Long Sing Energy’s stable chemistry lowers long-term TCO.

Working with a lithium ion battery energy density OEM supplier requires clear communication about your application’s power needs. Many customers focus solely on energy density specifications without considering power requirements. This leads to disappointed expectations when batteries can’t deliver the required current.

We always ask customers about their peak power demands, sustained power levels, and acceptable voltage sag under load. These factors shape our cell selection and pack design recommendations.

Temperature effects add complexity to the energy-power relationship. Low temperatures increase internal resistance, reducing both power capability and usable energy density. A battery rated at 250 Wh/kg at 25°C might only deliver 200 Wh/kg at 0°C, with power density dropping even more dramatically.

For outdoor applications in cold climates, we include heating systems that maintain minimum operating temperature. This adds weight and complexity but ensures consistent performance.

Conclusion

The energy density of lithium-ion batteries represents a critical specification that shapes product performance across electric mobility, energy storage, and portable power applications. Understanding the difference between gravimetric density (Wh/kg) and volumetric density (Wh/L) helps you select batteries that optimize for your specific constraints.

NMC chemistries deliver maximum energy density for weight and space-sensitive applications, while LFP options provide better value for cost-conscious and safety-critical deployments. The trade-off between energy density and power density requires careful analysis of your application’s duty cycle and performance requirements.

Working with experienced manufacturers who understand these relationships and maintain strict quality control processes ensures you get batteries that meet both specifications and real-world performance needs.

Request a custom quote and lead-time estimate for your high-density battery pack requirements today.

Frequently Asked Questions

Click to explore more information about Energy Density of Lithium ion Batteries

Q: Which battery has the best energy density?

A: Among commercially available batteries, lithium-ion batteries—especially those using NMC or NCA chemistries—offer the best balance of gravimetric (Wh/kg) and volumetric (Wh/L) energy density for most applications.

Q: What is the highest energy density Li-ion battery that I can purchase?

A: High-nickel lithium-ion batteries such as NMC 811 or NCA cells currently provide the highest commercially available energy density, typically reaching 250–300 Wh/kg at the cell level.

Q: Why is 400–500 Wh/kg so important?

A: The 400–500 Wh/kg range represents a key threshold where electric vehicles, aerospace, and portable devices could achieve significantly longer runtime or reduced weight, but this level is still mostly limited to laboratory or prototype technologies.

Q: Is there any battery that offers higher energy density than Li-ion?

A: Emerging technologies such as lithium-metal and solid-state batteries promise higher energy density than conventional lithium-ion, but they are not yet widely available for mass commercial use.

Q: What is the downside of an LFP battery?

A: The main drawback of LFP batteries is their lower energy density compared to NMC or NCA chemistries, which results in larger and heavier battery packs for the same energy capacity.

Q: What is the most energy dense AA battery?

A: Lithium primary AA batteries, such as lithium-thionyl chloride AA cells, offer the highest energy density among AA-sized batteries, outperforming alkaline and NiMH options.

Q: Which battery is better, LFP or NMC?

A: LFP batteries excel in safety, cycle life, and thermal stability, while NMC batteries are better suited for applications requiring higher energy density and compact design.