As a power tool battery OEM manufacturer, we deliver precision-engineered, high-discharge lithium-ion battery solutions designed to meet the demanding power, safety, and cycle-life requirements of professional power tools used in industrial and commercial environments.

While the landscape of the modern construction site and workshop has undergone a radical transformation, the roar of gas engines and the clutter of extension cables have been replaced by the hum of high-efficiency motors powered by advanced energy storage.

Today, the demand for high-performance cordless tools is at an all-time high, driven by the need for mobility, safety, and instantaneous power. At the heart of this revolution is the power tool battery, a complex piece of engineering that must deliver immense energy under the most grueling conditions.

Moving Beyond the Cord: The High-Performance Shift

Professional contractors no longer view cordless tools as secondary options for light tasks. From heavy-duty rotary hammers to high-torque impact wrenches, the expectation is parity with corded equivalents.

This shift has placed an enormous burden on lithium-ion batteries for power tools, which must now provide consistent voltage and high current without significant sag.

As a leading power tool battery OEM, Long Sing Energy has been at the forefront of this transition, developing cordless tool batteries that redefine the limits of portable power.

The “C-Rate” Factor: Extreme Discharge for High-Torque Tasks

Unlike a laptop or a smartphone battery that sips energy slowly, a drill battery must be capable of discharging its entire capacity in a matter of minutes. This is measured by the “C-Rate.”

For professional applications, high-drain lithium cells are required to handle discharge rates of 10C, 15C, or even higher. When a user engages a circular saw into a thick piece of hardwood, the power tool battery must surge with current to maintain RPM and torque.

Without this capability, the tool would stall, leading to inefficiency and potential motor damage.

Cell Selection: The Evolution from 18650 to 21700

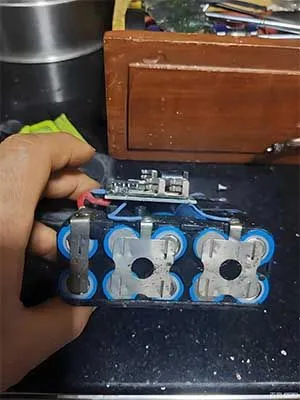

The choice of internal cells is the most critical decision in cordless tool battery technology. For years, the 18650 cell was the industry standard. However, as tools became more power-hungry, the industry shifted toward the 21700 format. When comparing 18650 vs 21700 for tools, the 21700 cells offer a larger volume which allows for lower internal resistance and higher energy density.

The following table highlights the technical differences that make the 21700 the preferred choice for a modern tool battery:

| Feature | 18650 Cell | 21700 Cell | Benefit for Professional Tools |

|---|---|---|---|

| Diameter (mm) | 18 | 21 | Higher Capacity |

| Length (mm) | 65 | 70 | More Active Material |

| Typical Capacity | 2.0Ah – 3.0Ah | 3.0Ah – 5.0Ah | Longer Runtime |

| Max Discharge | 15A – 25A | 30A – 45A | Higher Torque/Power |

| Heat Dissipation | Moderate | Superior | Extended Tool Life |

Using these advanced cells, a cordless drill battery can now deliver the same power as a corded tool while remaining ergonomic and lightweight.

Vibration and Impact Protection: Rugged Engineering

A job site is a violent environment for electronics. A cordless battery must survive drops from ladders, the constant vibration of a reciprocating saw, and the dusty environment of a masonry project. Long Sing Energy utilizes an impact-resistant battery design that features reinforced outer shells and internal damping.

Mechanical engineers design the internal cradle of the power tool battery to isolate the cells from the housing. This ensures that even if a drill battery replacement is dropped on concrete, the internal connections—typically high-conductivity nickel strips—remain intact. This level of durability is what separates professional power tool batteries from consumer-grade alternatives.

From rugged power tools to demanding mobility and energy systems, the same vibration-resistant battery engineering also drives performance across multiple industries.

In electric mobility and light electric vehicles, high-discharge lithium-ion packs must survive constant road shock while delivering stable power for acceleration and regenerative braking.

For energy storage systems, mechanical stability ensures long-term cycling reliability in containerized and cabinet-based installations.

In recreational vehicles, vibration-tolerant battery packs protect onboard electronics during long-distance travel and off-road use.

For unmanned aerial vehicles, impact-resistant and lightweight lithium-ion batteries are critical to flight safety, endurance, and payload stability.

These applications all rely on the same rugged battery architecture developed for professional power tools—making them ideal extensions of our high-performance cell and pack design expertise.

Thermal Efficiency: Keeping Cool Under Pressure

Heat is the primary enemy of lithium-ion chemistry. During continuous heavy-duty use, such as mixing mortar or drilling deep holes in steel, a cordless battery generates significant internal heat. If the temperature exceeds safe limits, the Battery Management System (BMS) will trigger a shutdown to prevent a “thermal runaway” event.

Long Sing Energy integrates advanced thermal pathways and heat-conductive materials within the pack. By optimizing the airflow and cell spacing, our cordless tool batteries can sustain high-power output for longer durations without overheating. This thermal stability is crucial when a professional is looking for a reliable replacement battery for power tools that won’t fail during a critical phase of the project.

Customization and OEM: Tailoring the Interface

Not all tools are created equal. As a premier power tool battery OEM, Long Sing Energy understands that the interface between the tool and the battery is just as important as the cells inside. Each brand has specific communication protocols and physical latching mechanisms. Whether it is a standard cordless drill battery or a specialized tool battery for outdoor power equipment, customization is key.

Our R&D team works closely with partners to design housings that are ergonomic and perfectly balanced for the specific tool’s center of gravity. This ensures that the electric drill batteries do not cause operator fatigue while providing the necessary “juice” for the job.

The Long Sing Energy Advantage: Case Studies

Long Sing Energy’s reputation is built on delivering high-performance energy solutions that outlast the competition. We specialize in providing a power tool battery that maintains its capacity even after hundreds of charge-discharge cycles. Below are examples of battery packs engineered for specific professional applications:

| Application | Pack Configuration | Voltage (V) | Capacity (Ah) | Discharge Peak |

|---|---|---|---|---|

| Compact Impact Driver | 5S1P (18650) | 18V | 2.0Ah | 30A |

| Heavy-Duty Hammer Drill | 5S2P (21700) | 18V | 8.0Ah | 90A |

| Industrial Grinder | 10S2P (21700) | 36V | 6.0Ah | 120A |

| Portable Table Saw | 15S3P (21700) | 54V | 12.0Ah | 150A |

Whether a client needs a high-capacity drill battery for a day-long framing job or a lightweight cordless battery for overhead work, Long Sing Energy provides the precision and power required.

Conclusion: Powering the Future

The evolution of power tool batteries has been a journey of moving from “good enough” to “better than corded.” By focusing on high C-rate discharge, 21700 cell technology, and ruggedized mechanical housing, Long Sing Energy ensures that every power tool battery we produce meets the high standards of the professional tradesperson.

When the time comes for a drill battery replacement, pros look for reliability and safety. Through our expertise as a power tool battery OEM, we continue to push the boundaries of what is possible, ensuring that the cordless tool batteries and power tool batteries of tomorrow are even more powerful, safer, and longer-lasting than those of today.

Explore how high-discharge lithium-ion power tool battery from OEM manufacturer can elevate your next project—contact us today to discuss your OEM battery requirements and receive a customized solution.